Composite Models and Components

Design and Fabrication of Composite Models and Components

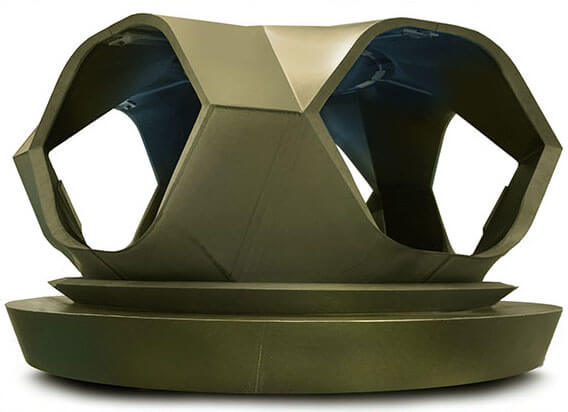

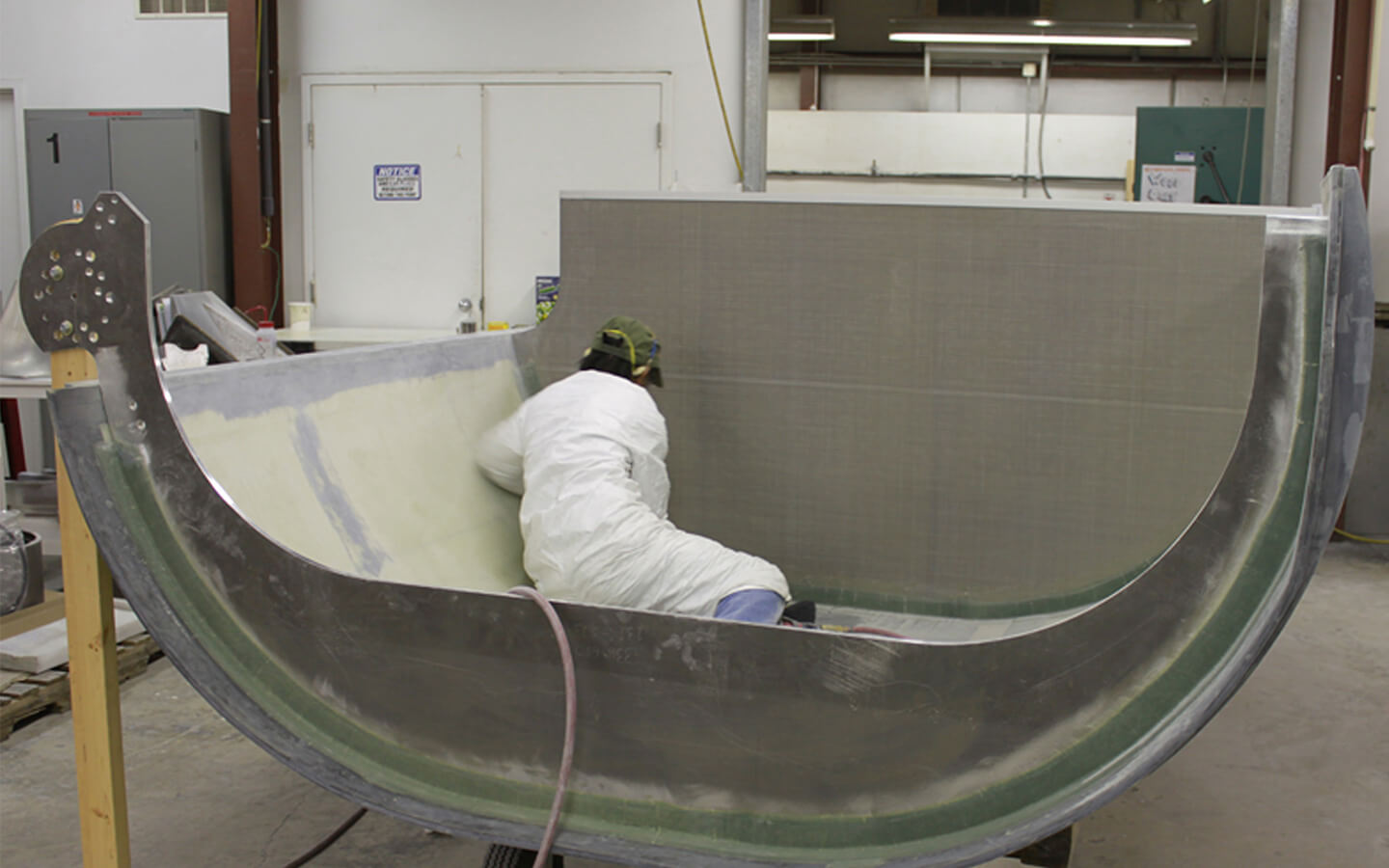

Calspan has provided composite models and components since the 1970s. Our wide ranging skill sets and in house capabilities have allowed us to support programs from simple test panels to RCS models and even complete fuselages. Vertical integration means Calspan has the people and equipment to take your project from concept through manufacturing, instrumentation and assembly entirely in house. Calspan works with customers to define the critical characteristics early on. Is exterior appearance and finish most important for a press event? Must stiffness match aircraft values to perform crash or sled testing? Is the model for an RCS test? Calspan can deliver. Our innovative tooling approaches can reduce first unit lead time by months compared to traditional approaches.

Vertical Integration

Calspan's vertical integration business model places all phases of test article development under one roof. From concept through delivery we can maintain control and security.

Lean and Agile

Calspan is a small company staffed with experienced and skilled people dedicated to excellence. The wide variety of projects we have delivered provides a broad base of knowledge.

Low Cost Tooling

Calspan consistently drives tooling and NRE costs down through the creative use of foam, wood and Aluminum tooling.

FEATURES AND BENEFITS

Two large autoclaves for curing large components.

Calspan can manufacture custom shop ovens for curing even larger components, up to the physical size of the room.

Full scale aircraft Mock-ups have been manufactured with both female (OML) molds and male (IML) molds.

Expertise in fixed wing, rotorcraft, space and hypersonic models.

Complete fabrication is performed in our 93,000 sq.ft. facility including machining, assembly, instrumentation, inspection and model buy-off.

Design and fabrication services are available for wind tunnel related equipment including: model positioning systems, fan and compressor blades, and tunnel upgrade and overhaul services.

Wind tunnel testing can be performed at Calspan’s Transonic Wind Tunnel in Buffalo, New York.

- Facility

- 93,000 square foot secured facility

- Quality

- AS9100/ISO9001

- NADCAP

- Manufacturing

- CNC summary

- Autoclaves

- Clean rooms

- Instrumentation lab

- Large assembly areas