Flutter Exciter Systems

Features and Benefits

The Calspan Flutter Exciter is a uniquely capable and proven system that supports aircraft OEMs and other customers to achieve their aircraft flight flutter clearance needs. The Calspan system excites the aircraft flight surfaces using a fixed vane with rotating slotted cylinder; as the cylinder rotates it deflects flow up and down and matches the aerodynamic effect of an oscillating trailing edge flap. The rotating cylinder architecture requires significantly less energy than oscillating flaps and is easier to control.

For flight test operators working against the clock to clear a flight testing envelope, an All-Weather Exciter offers extra flexibility when facing rain, light clouds, or other ill-timed weather. Calspan has released a new line of All-Weather Flutter Exciters, which perform just like our industry standard Exciters used in flight testing for decades, but with the added benefits of weather proofing upgrades and additional RTCA DO-160G qualification tests.

Custom Configurations

Calspan's Flutter Exciter systems are manufactured within our facility to meet the exacting requirements of our customers.

Quality Focused

Our Flutter Exciter Systems are manufactured within our robust AS9100 D and ISO:9001:2015 Quality Management System.

The Calspan Flutter Exciter system can be configured to operate up to five exciters; two exciters can be operated simultaneously. Our Flutter Exciter is built using commercial/industrial grade electronic components, the system has undergone a wide range of DO-160 tests and is ruggedized for use in flight test applications.

Each 120 in² Exciter produces a maximum dynamic load of ±118 lbs (±525 N) at 350 KEAS for frequencies 0-50 Hz. By varying the cylinder slot opening, the dynamic load from each Exciter can be reduced to 25%.

Each 60 in² Exciter produces a maximum dynamic load of ±59 lbs (±262 N) at 350 KEAS for frequencies from 0-70 Hz and the magnitude of the load can be adjusted in a similar manner.

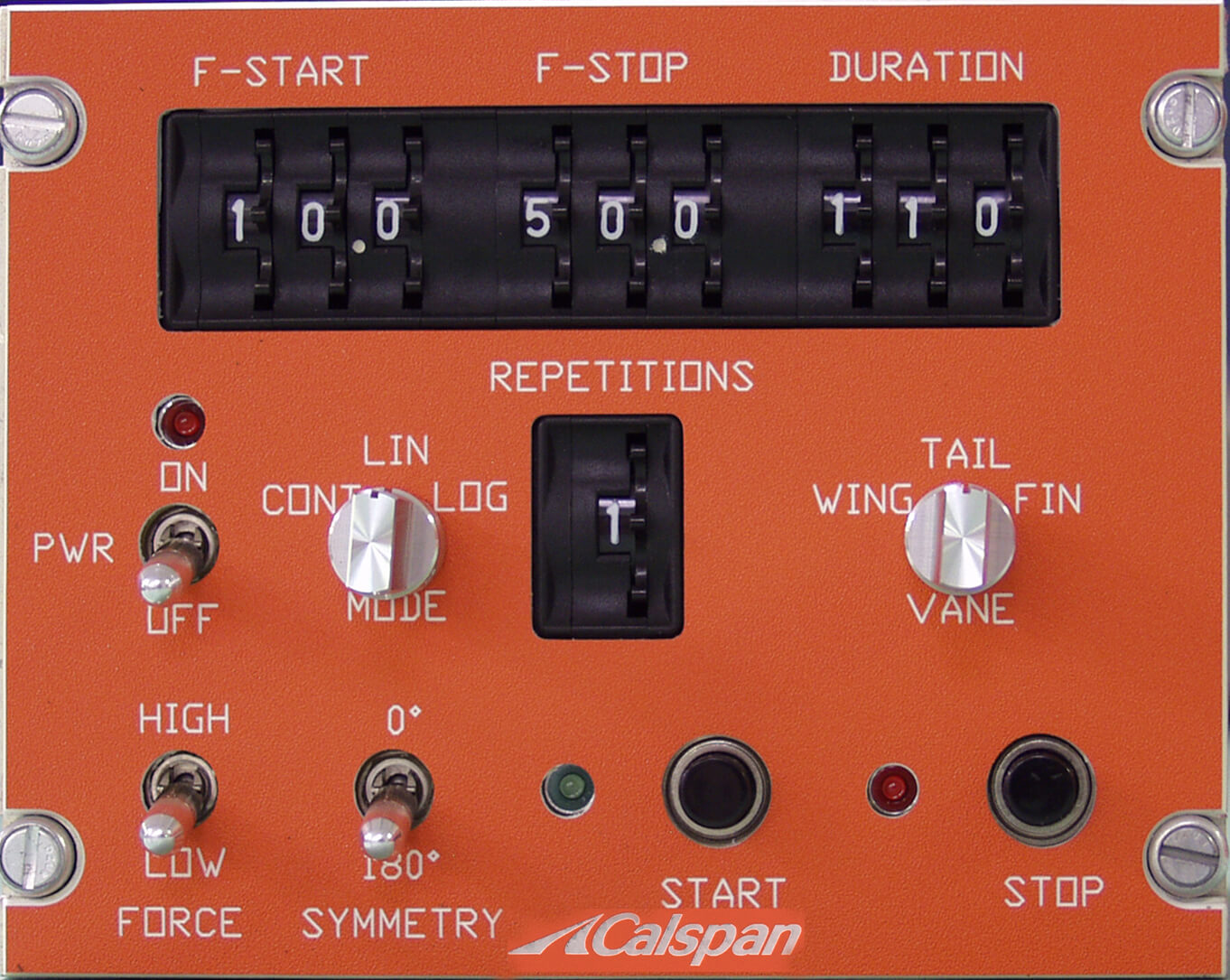

The Cockpit Controller is designed to be mounted in a standard cockpit mounting rack (MS25212), if desired. The Cockpit Controller provides pilot-operated controls to allow selection of all exciter functions.

The Avionics Box contains the support electronics required for the system and also includes provisions for installation in a standard 19” rack. The Avionics Box is built from industry accepted materials to provide adequate protection against EMI, shock, and vibration. Analog signals are provided from the Avionics Box for the customer data system.