Turbomachinery

Design and Manufacture of Turbomachinery Test Articles and Equipment

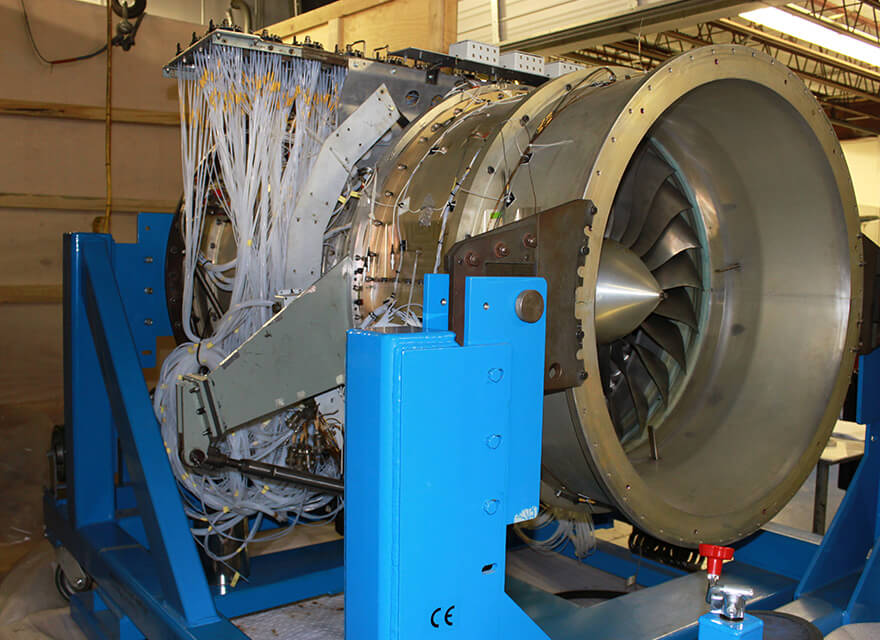

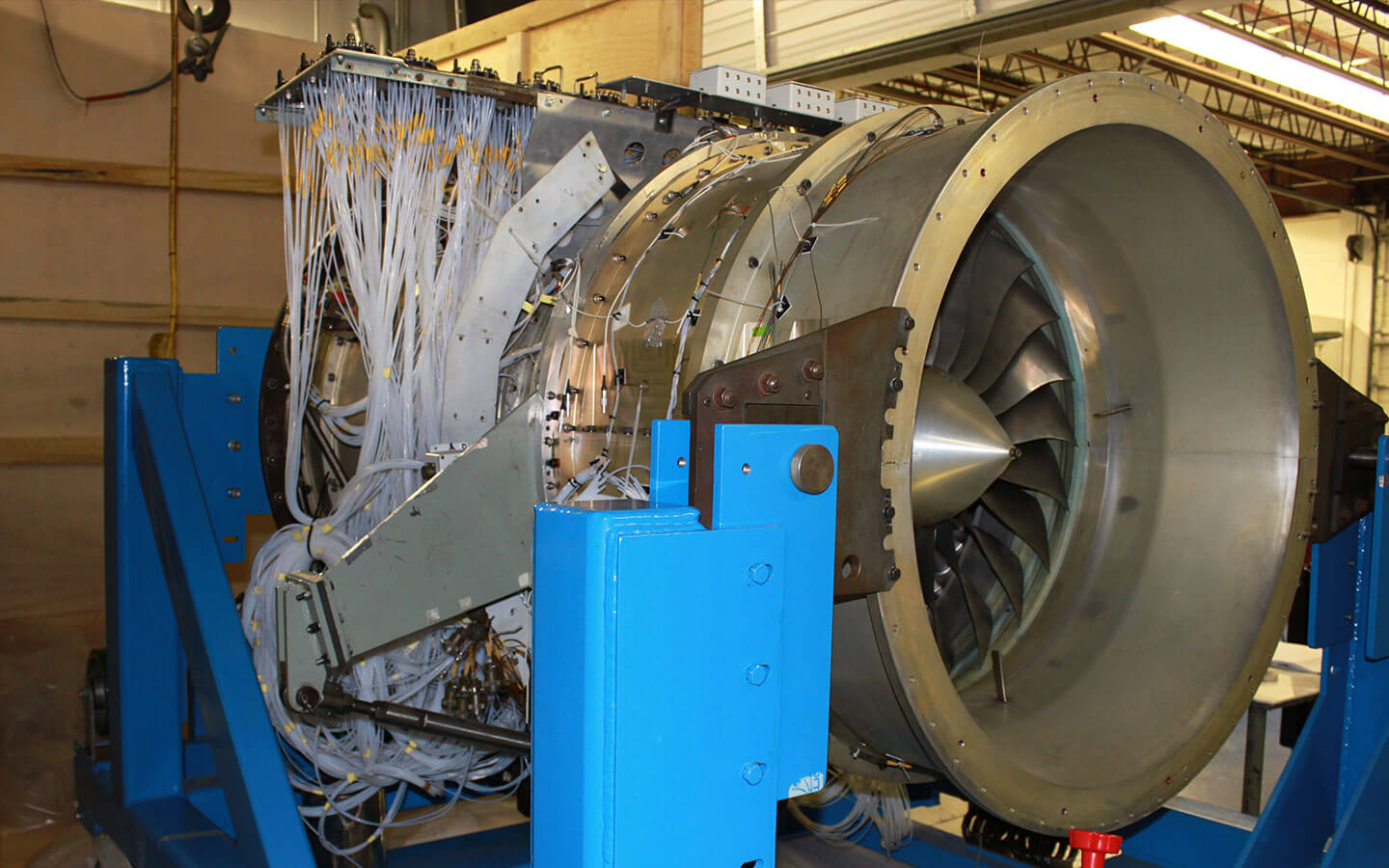

For over 20 years, Calspan has designed and manufactured full-scale turbomachinery test rigs for the world's gas turbine engine manufacturers. As a vertically integrated supplier, Calspan combines the ability to engineer, manufacture, instrument, and assemble complex rigs and other experimental equipment. By interpreting requirements, collaborating to solve complex technical problems, and achieving your experimental needs, our team of experts is dedicated to your success. Our projects include fan, compressor, combustor, turbine, and many other special purpose test rigs.

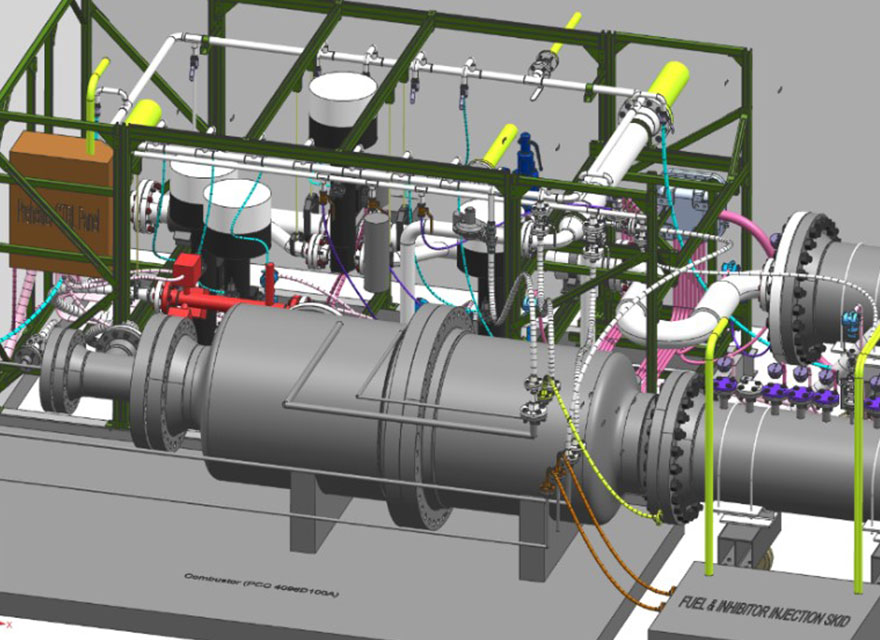

We also design and manufacture all types of turbomachinery test equipment. From special component test fixtures to special facility interface hardware, equipment and systems, Calspan has the capability to ensure your successful test.

One-Stop-Shop for Rigs

Our vertically integrated in-house capability, from rig concept through to commissioning, minimizes hand-offs, assures quality, and reduces cost and lead-time for all turbomachinery rigs

Reduce Stress for Your Team

We are experts at designing and manufacturing turbomachinery rigs and test equipment. We can free up your team to focus on critical product development efforts.

Test Article Experts

Talk to us about your test article and test equipment needs. Our experts are ready to help you define a test article that best meets your technology or product validation goals.

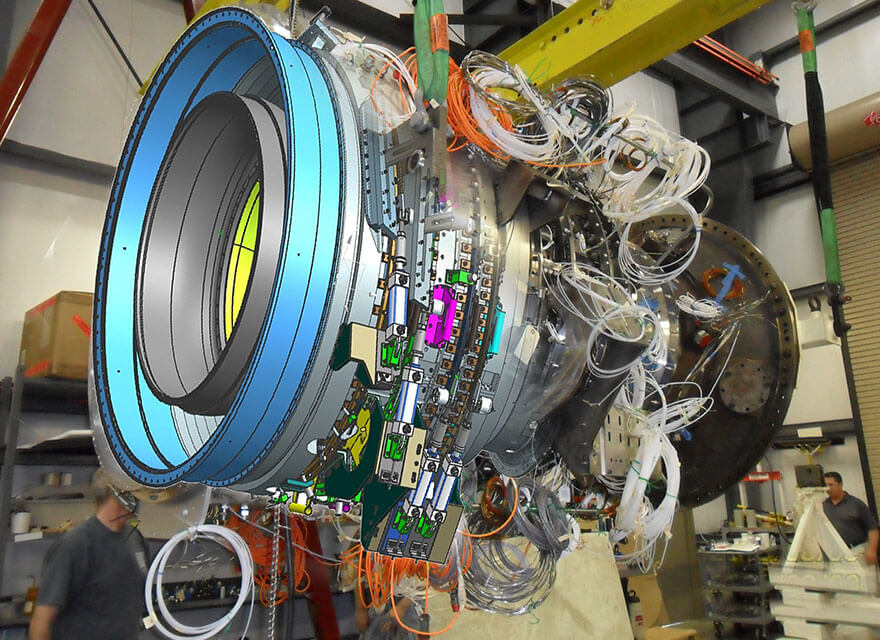

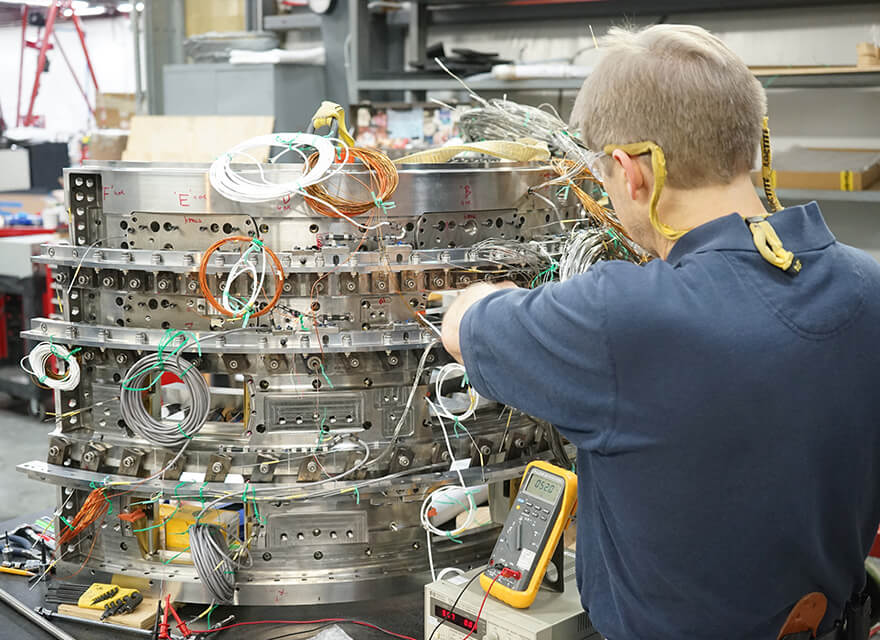

Our team thrives on working closely with our gas turbine and other turbomachinery test rig customers to define and deliver complex test articles to validate new technologies and products. Often starting from our customer’s aerodynamic definition, we have the in-house capability to fully engineer the test article (including the instrumentation suite), manufacture the parts, apply the instrumentation, assemble the rig and often support testing in our customer’s or third party test facilities. The entire process is executed within our robust ISO9001:2015/AS9100 (Rev. D) quality management system.

Calspan has executed a wide range of turbomachinery rig projects for our gas turbine aero engine, industrial engine and other turbomachinery OEM customers over the last 20 years:

- Fan Rigs – full scale and sub-scale, single-stage (civil) and multi-stage (military), often used to validate performance, noise and blade containment.

- Compressor Rigs – engine scale, sub-scale and super-scale multi-stage axial and single stage radial compressor rigs used to characterize performance/operability and establish variable vane schedules.

- Combustor Rigs – single burner, multi-sector or full annular, used to characterize aerothermal performance, combustion products and combustor operability.

- Turbine Rigs – full scale and subscale, cold flow (visualization), warm-flow and hot-flow, single and multi-stage (including contra-rotating), used to calibrate sub-system simulation models and validate stage and overall system performance.

- Other Complex System Rigs – including propulsion simulators, un-ducted fan models, rotating secondary flow rigs, rocket turbo-pump rigs, bearing and seal rigs, steam turbine rigs and flow visualization rigs.

- Development Engines and Cores – we also instrument and assemble the engine OEM’s demonstrator engines and development cores.