Crash Lab Facilities & Equipment

Calspan Crash Lab Test Facilities and Equipment

For those in North America seeking to improve, expand, or build a new vehicle crash lab test facility, the Calspan-MESSRING partnership offers the ideal solution. MESSRING is the gold standard for vehicle crash test equipment and Calspan offers extensive "hands-on" crash test and test facility construction experience. We help customers define requirements and make the right choices when it comes to location, equipment, and layout.

Plus, we’ll keep you operational. We understand the importance of staying on schedule. While we’re servicing your crash lab, you can test at ours. Because Calspan has MESSRING products, you’ll be able to get the data you know and trust. Don’t miss an opportunity to upgrade over a busy schedule.

Furthermore we’re local. Located in the North American Market, we can make purchasing equipment easier. Removing language, location, and time zone barriers, you’ll be able to get your questions answered quickly.

Crash lab & Test Equipment

Calspan’s crash lab and team can help you choose and acquire the MESSRING equipment that best suits your needs, including, propulsion system, microtrack a film pits, plus so much more!

Facility Design & Upgrade

Let Calspan help you with real estate identification and acquisition, facility layout and design, construction management, equipment installation and commissioning.

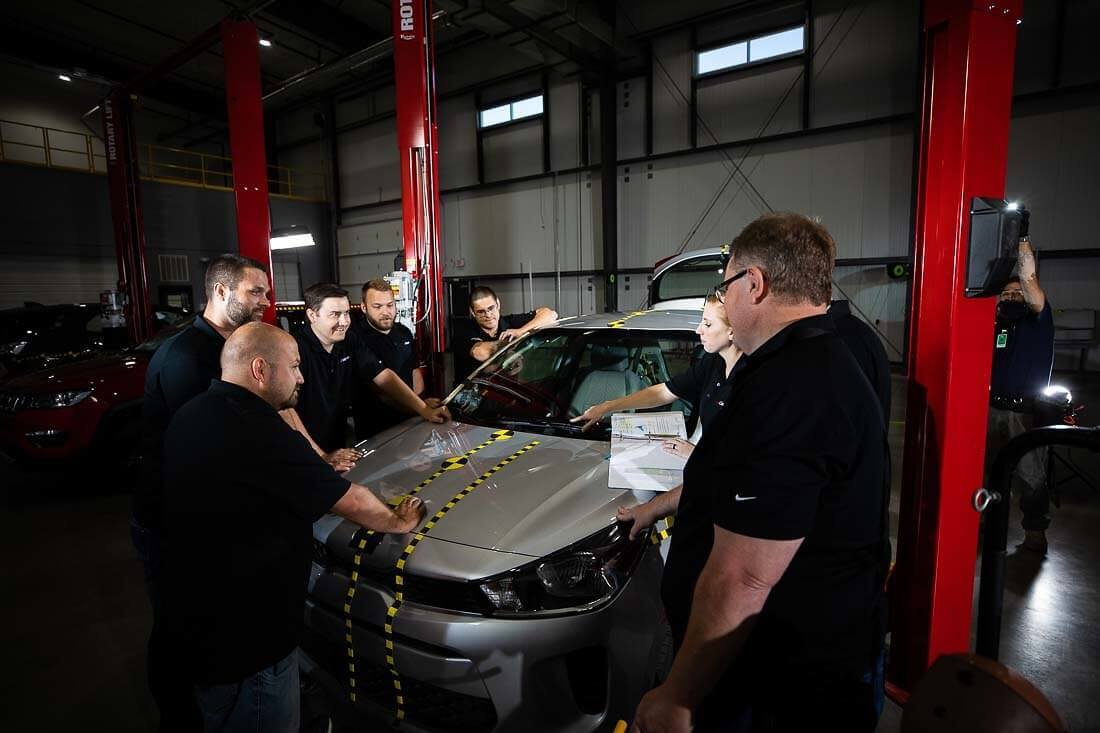

Training Services

Since 2018, Calspan has been a regional source for MESSRING services, providing expert support with training on how to properly use the MESSRING crash test equipment.