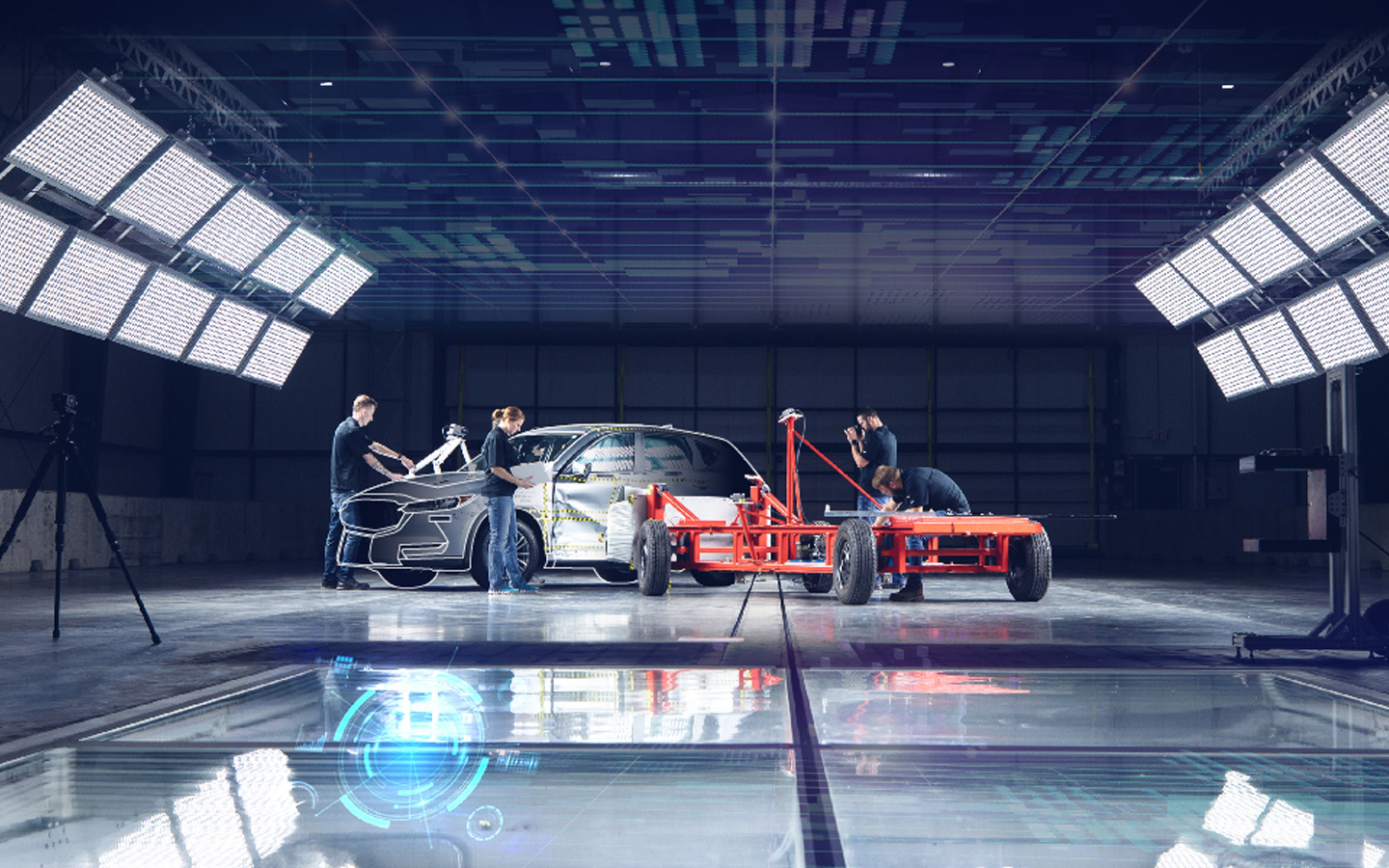

Vehicle Crash Test Services

Supporting Vehicle Development / Production Verification

Calspan is world renowned for its experienced, flexible and collaborative staff and for having the most modern and secure vehicle crash test facility in the United States of America. Calspan performs crash tests in support of a vehicle’s complete life cycle. Tests supporting:

- Research and Benchmarking

- Structural Crashworthiness

- Occupant Protection

- Verification / Validation to Current and Proposed Global Standards

- Field Re-Creation Tests

Spanning everything from crash tests on frame rails, bumpers and front-end structures into high resolution load cell walls to validate structural CAE simulations to crash tests on prototype electric vehicles requiring a significant amount of instrumentation (100+ vehicle data channels, highly instrumented ATDs, etc.), CMM and vehicle modification/re-build between tests.

Calspan is

Calspan is

TISAX® Certified

New, Modern Test Facility

A fully enclosed, secure and temperature controlled lab with unique capabilities like MESSRING’s vehicle propulsion system, micro-track, photo pits and high-resolution load cell walls.

Flexible Scheduling

Calspan understands vehicle development is dynamic. When changes occur, Calspan does “whatever it takes”. Including, rescheduling tests, working extended hours and even weekends.

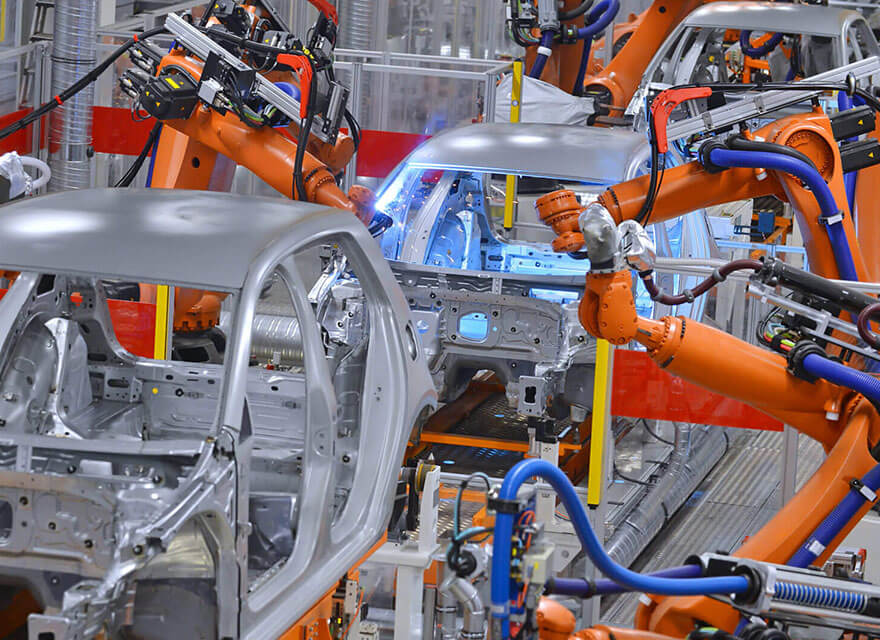

3-4 Crash Tests Per Day

World-class, efficient facility run by a huge, dedicated staff of experts with a tremendous amount of equipment at their disposal. Hence, awarded, "Crash Test Lab of the Year."

YOUR DEVELOPMENT PARTNER

Throughout the test process, Calspan encourages customer involvement as much, or as little as a customer may desire. This includes working on test vehicles, participating with test set-up and the use of tools. Should a customer be unable to travel to Calspan, Calspan offers of number of digital collaboration tools, including a revolutionary way for customers to remotely “participate.”