Formula SAE Tire Testing Consortium

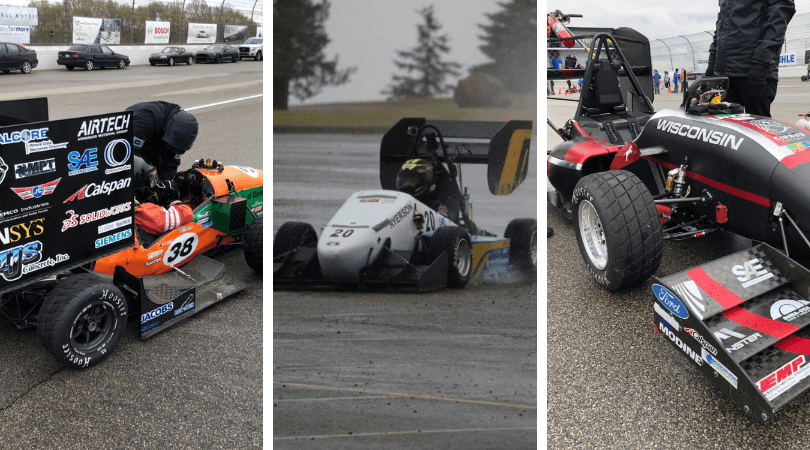

Participating in Formula SAE gives students an opportunity to design and develop a small Formula-style race car.

FORMULA SAE

As part of the program, the prototype race cars are evaluated for their potential as a production item. Each student team must abide by a series of rules, whose purpose is both ensuring on-track safety (the cars are driven by the students themselves) and promoting solid engineering and project management practices.

History

The FSAE TTC has been aiding students and the next generation of engineers since 2005.

The FSAE TTC came out of a 2004 SAE Motorsports conference where it became apparent that there was student interest in tire data while designing their cars. Without real tire data, the students would have to guess most parameters required to design the car’s chassis and suspension. This would be a significant gap in an engineering design competition where the tires are the most important vehicle component.

The TTC founders worked with Calspan to develop a way to get data for these students that was affordable and professional. Calspan agreed to provide the same quality data used for its professional motorsports customers at a greatly reduced cost for the members of the consortium. The TTC was developed out of, and still maintains the philosophy of, making high-quality tire data accessible to all student teams and the next generation of engineers. Giving these students the opportunity to develop new skills that are in high demand in the automotive industry.

The first round of testing was conducted in 2005, where approximately 27 teams benefited from this data. Since then, a total of eight test sessions have been completed and have helped teams from more than 565 schools around the world. This large, and growing, number of participants as well as generous support from tire manufacturers, has helped to keep the cost to the schools at a minimum.

Since the beginning, tires for the TTC have been donated by various tire manufacturers. The TTC pool of data includes more than 430 tests on over 40 tire constructions. In exchange for donating tires to be tested, manufacturers also get access to the test data collected for the TTC. This, in turn, helps students two-fold. The data helps students determine the best way to design their car and influence what tires to purchase, and tire manufacturers are able to develop better tires for FSAE racing based on the data gathered on the tests performed at Calspan. This synergy created is another mutually beneficial result that has blossomed out of the TTC.

Calspan's Involvement

Calspan is the sole provider of tire data for the TTC.

Calspan has been a research facility in Buffalo NY since 1940. Calspan began testing on ground vehicles in the 1950s. In 1973, they began performing tests on the world's largest and most powerful indoor flat track tire testing machine. The machine has run over 100,000 tests and has supported the world leaders in tire technology, particularly in the world of motorsports and high-performance tires.

The data collected on the Calspan Tire Test Machine has paved the way for Computer Aided Engineering (CAE), through mathematical tire models such as Magic Formula/ Pacejka. This data is invaluable to car manufacturers and tire developers alike. After all, the only place a car comes in contact is where the rubber meets the road!

The TTC founders knew how important it was for these students to get access to tire data. Calspan’s leadership also saw the value in providing this data in a way that made it accessible to all teams and offers heavily discounted testing for the TTC.

Want to learn more about Calspan’s Tire Testing Capabilities? Click here.

The Data

To date, eight rounds of testing have been completed with the intention to continue to test in the future.

Tests are conducted on the Calspan Tire Research Facility flat-belt tire test machine using 120 grit belt paper and a velocity of 25 mph which is the average velocity of an FSAE car during a race event. Static and dynamic (rolling) spring rate tests are run in conjunction with the lateral force tests. These tests have been designed specifically to the TTC competition to best simulate average drive patterns and velocity used in FSAE race events.

The exact details of the tests (specific loads, inclination angles, etc.) are revised in each round of testing, but the spirit of the tests remain unchanged. Members may send a representative to witness any future tests in person (interested parties please contact Dr. Kasprzak for details). Video of some testing is available.

To learn more, visit the official FSAE TTC webpage, or log in to download your data set.

How to get Involved

Visit the public FSAE TTC webpage and fill out the registration form. Payment of $500 USD must accompany the registration form to be eligible for data download.

All completed forms should be submitted to kasprzak@fsaettc.org and one of the TTC volunteers will help you work through the registration process.

Not sure if your FSAE Team is already part of the consortium? Download the FSAE TTC Finances and Registered Schools spreadsheet and search for your university name.

Already a Member?

Visit our secure forum to download data and connect with other TTC members.

Click here for resources to download Calspan’s logo for your FSAE vehicle.